All Posts (bam)

All Posts (bam)Re: putting together my 355 LT1, questions |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

The book "How to rebuild small block Chevy LT1/LT4 Engines" says about these plugs with the hole in the front; "these are an oddball size you may be forced to reuse them. Coat them with locking compound then apply a two part epoxy to assure a good seal" I just reused mine. I was wondering about head bolts, can I reuse them, is that wise or should I get new ones? As for the oil galley plugged by that ball in the back, I told the machinist to remove it and then clean the motor and then reinstall. Hopefully he did. I checked the mains with plastiguage and have 2 - 2 1/2 thou. on all. Still have to check the rod clearance.

Posted on: 2012/2/4 0:21

|

|

Transfer Transfer

|

||

Re: putting together my 355 LT1, questions |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

What about break in oil and filter? Change after about 30 min of running and then again at 100 mi? Brand, weight of oil?

Posted on: 2012/2/2 14:26

|

|

Transfer Transfer

|

||

Re: putting together my 355 LT1, questions |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Will thanks a bunch!!

Posted on: 2012/2/2 3:41

|

|

Transfer Transfer

|

||

putting together my 355 LT1, questions |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Picked up my block, crank & pistons from the machine shop today, will be putting it together myself over the next few days, weeks. A few questions; (93 LT1, 355, hot cam, Mahle pistons, recon. rods)

1. What head gasket(I know there is one that bumps the comp. ration up a tiny bit, is that the impala)? 2.Where can I find the oil pump drive that interfaces with the cam drive? Checked Rock Auto NA 3.I have added Trick Flow 185 heads, can I still get by with my FIC 24lb injectors? 4.When I prime the oil pump with the intake off how long can I wait before then putting the intake on and the motor in the car? (is it a problem if it is a week or two) 5.Any other advice is appreciated, things to remember to do while in there (it's been 15 yr since I last assembled a motor)? Thanks

Posted on: 2012/2/1 1:57

|

|

Transfer Transfer

|

||

Re: high volume oil pump or standard? |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Thanks Will.

Posted on: 2012/1/11 16:33

|

|

Transfer Transfer

|

||

Re: high volume oil pump or standard? |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

I bought a M55 should I just take it back or what should I look for in the casting?

Posted on: 2012/1/6 18:19

|

|

Transfer Transfer

|

||

high volume oil pump or standard? |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Am rebuilding my 93 LT1 engine. Hot cam, new heads (trick flow), bored 30 over. Planning to rev no higher than 6200, opened up the mains and rods to 20 to 25 thou. a stock oil pump should be fine right? Any thoughts?

Posted on: 2012/1/6 16:22

|

|

Transfer Transfer

|

||

Re: My LT1 rebuild |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Who is going to do your new tune?

Posted on: 2011/12/1 14:53

|

|

Transfer Transfer

|

||

Re: New Wheels and Corsa Pics |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Really nice!!

Posted on: 2011/11/30 22:41

|

|

Transfer Transfer

|

||

Re: To all my corvette friends |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Welcome back!

Posted on: 2011/11/30 22:40

|

|

Transfer Transfer

|

||

Re: Carbon Fiber Finishing on Interior Components |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Looks very nice! Thanks for posting, I never knew this kind of stuff was out there.

Posted on: 2011/11/30 3:33

|

|

Transfer Transfer

|

||

Re: My LT1 rebuild |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

Wow, 10 mo. and I thought the guy doing my block was slow (been wating 2 mo. now, we'll see if he can "beat" your record, haha) Thanks.

Posted on: 2011/11/29 14:00

|

|

Transfer Transfer

|

||

Re: My LT1 rebuild |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

tjpreul who did your machine work in Columbia, were you pretty satisfied with them? Did they also balance the engine? I notice you have the white gauges, how difficult was that to put in? Can you post a photo, I think the white gauges look really nice.

Posted on: 2011/11/28 15:37

|

|

Transfer Transfer

|

||

Re: My LT1 rebuild |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

I had already installed Exotic Muscle LT headers with the hot cam and 1.6rr's, it sure was fun to drive for those 500 or so miles. I think my real mistake was bumping the rev limit up to 6200 rpm.

Posted on: 2011/11/27 19:40

|

|

Transfer Transfer

|

||

Re: My LT1 rebuild |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

tjpreul how is your build coming? Thanks for letting me post a couple of question here on your thread! Keep us up to date on your motor.

Posted on: 2011/11/27 3:36

|

|

Transfer Transfer

|

||

Re: My LT1 rebuild |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

I used LT4 springs, I know they are marginal at best with stock LT1 valves (heaver than LT4 valves). I think I was getting to valve/lifter float at 6x rpm plus. I am rebuilding my motor right now, new pistons, rings, bored .030, new lifters (probably GM LS6 type) and I am thinking of Trick Flow 185 heads. Any thoughts.

Posted on: 2011/11/27 3:33

|

|

Transfer Transfer

|

||

Re: My LT1 rebuild |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Will thanks, the lifters all look very good, the bearings all smooth, the roller surface nice and smooth too. The body of the lifters have scratches on them though. The "dents" in the cam are so small that when you run your finger over them it is impossible to feel them. I really hate to just toss that cam and spend 200 for another hot cam, I really like the hot cam, just right for what I wanted out of my motor, but better safe than sorry, I'd rather toss it than take a chance unless someone here can tell me different who really knows. Would more pix help?

Posted on: 2011/11/26 23:08

|

|

Transfer Transfer

|

||

Re: My LT1 rebuild |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

"When a lobe is damaged from lifter bounce it's always on the closing side flank of the lobe." Not to hijack this thread but I have a question about this. The cam rotates clockwise when you stand in front of the engine and look at the cam, right? Then is this kind of wear on the right side of the lobes or the left? My hot cam that I took out of my recent LT1 cam swap (only 500 mi on the cam before the motor went bad) has a strange "dent" in each lobe. It is on the right side of each lobe when you look at the front of the cam. Is this the "lifter bounce" you speak of? Is a cam reusable when it shows this kind of wear? I really appreciate your feed back on this as I am wondering if I need to replace my almost new hot cam because of this or if it is ok to reuse. I know I need new lifters. Here are some pix of the wear. Thanks for letting me post this in your thread.

Posted on: 2011/11/24 15:06

|

|

Transfer Transfer

|

||

Re: My LT1 rebuild |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

The stock cam from my LT1 build looks the same (see pix). How could it be that the lobe would hit a rod on a stock stroke motor? Interesting. My motor had 100x on it.

Posted on: 2011/11/24 14:56

|

|

Transfer Transfer

|

||

Re: 93 6 spd clutch master to slave hard line, where to find? |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

I'll get back when the part comes. At least the price was decent. A major Vett vendor had the exact same line for 130. plus shipping pushing the price over 140. A Chevy dealer in NY had two of them but I hate dealing with people in NY (no offence to any NY's out there). I live in a small town and no one here had seen a fitting like the one on that line.

Posted on: 2011/11/11 3:03

|

|

Transfer Transfer

|

||

Re: Top end swap on my 92 LT1 to the LT4 (fresh start) |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

Nice, got any pictures? Post some if you can.

Posted on: 2011/11/11 2:59

|

|

Transfer Transfer

|

||

Re: My LT1 rebuild |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

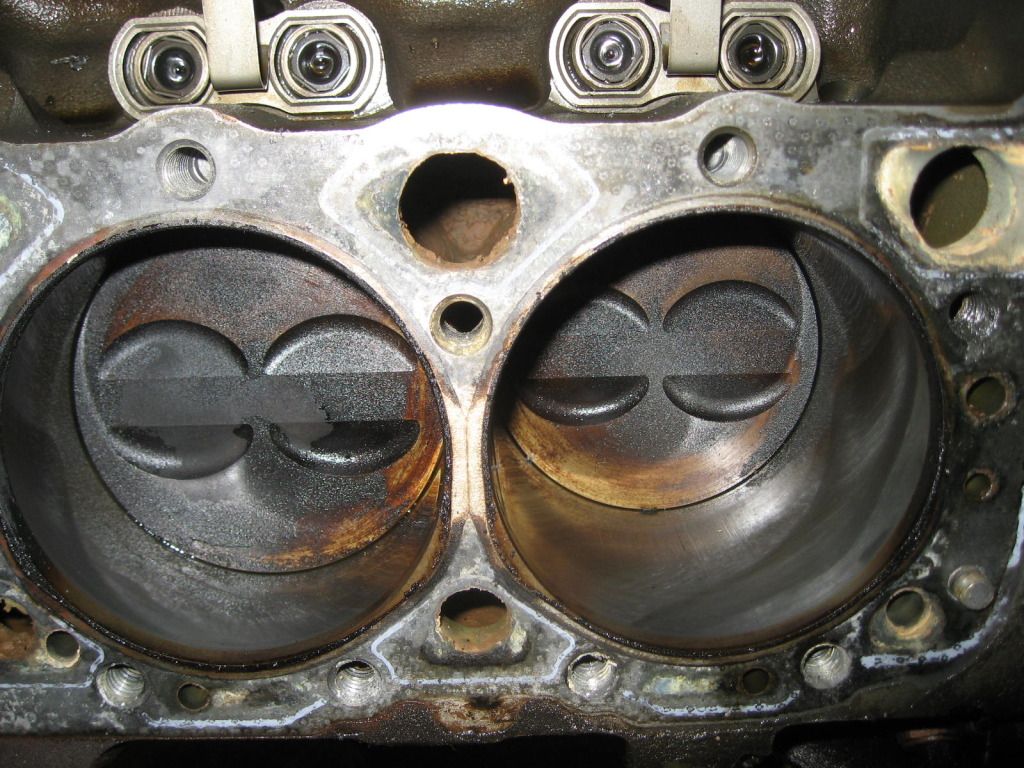

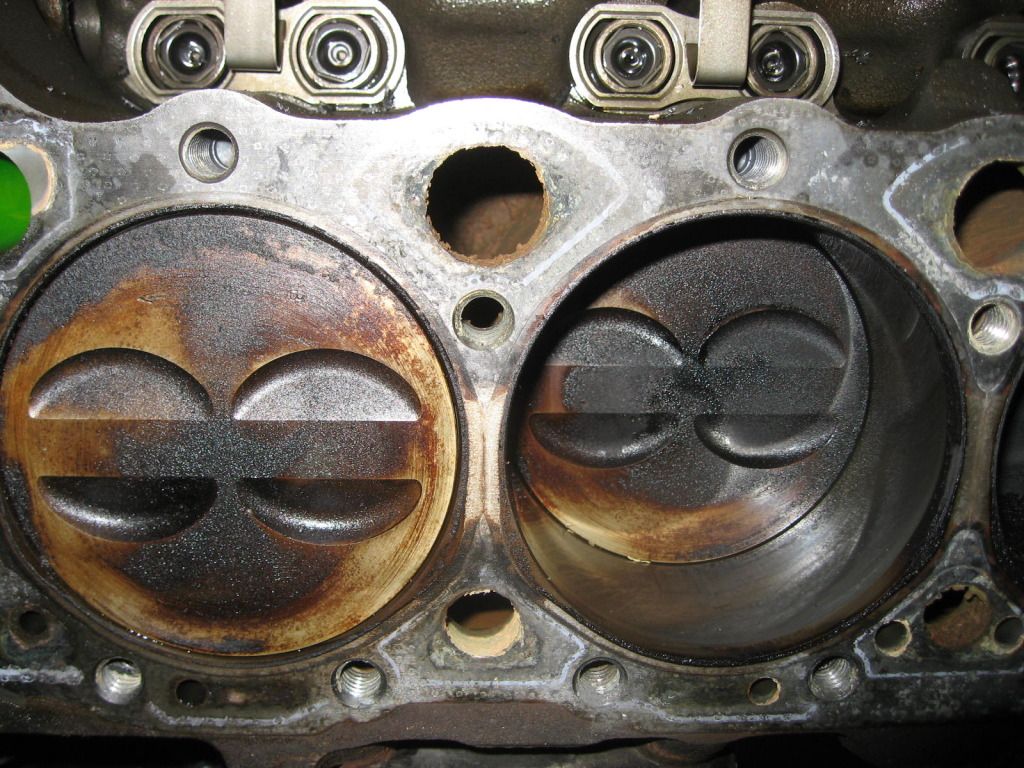

Nice looking stuff. I can't believe how clean your piston tops are. Mine have lots more carbon and cooked oil. DSC04475.JPG I assume this pix is your new motor? What is in it? Love builds for the LT1, thanks for posting.

Posted on: 2011/11/10 14:57

|

|

Transfer Transfer

|

||

Re: 93 6 spd clutch master to slave hard line, where to find? |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

Steve, thanks, they had the clutch line, ordered this morning.

Posted on: 2011/11/10 14:14

|

|

Transfer Transfer

|

||

Re: 93 6 spd clutch master to slave hard line, where to find? |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

You guys are a wealth of info. Thanks. I took the hose to the auto parts store, they build hydraulic lines but they said they had never seen a fitting like the one on both ends. The Chevy dealer said the part is discontinued, so I was feeling pretty helpless. I will try the implement dealer, they build hydraulic hoses too, maybe they can make it.

Posted on: 2011/11/10 2:35

|

|

Transfer Transfer

|

||

93 6 spd clutch master to slave hard line, where to find? |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

I am replacing both the clutch slave and master. The hard line running from one to the other is stripped out where it threads into the slave. This GM part #12509314 is discontinued. I can't find a replacement anywhere, can someone help? Thanks.

Posted on: 2011/11/9 22:38

|

|

Transfer Transfer

|

||

Re: pulling the motor - question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

Yes I guess if it need replacing then I have to spend the money anyway and I'd hate to have to tear the car back down in a few months if I reuse the dual flywheel and it goes out, I'd much rather replace it now. Where can I find the whole kit, flywheel and clutch together?

Posted on: 2011/10/13 13:58

|

|

Transfer Transfer

|

||

Re: pulling the motor - question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

Are you talking about putting a mark on the front part flywheel and one on the back then moving the back part of the flywheel counter clockwise and measure the distance? I did that and it is less than the factory maximum of 1 3/8" mine is about 1". It's the flywheel surface that I am worried about. I am wondering if I will really feel a difference in a light weight flywheel costing $450+ or is it something you notice only when racing, if so then I really don't need it, if it is like adding 30 horse power then I might consider it. Otherwise if I can reuse my stock flywheel then that's 450 to spend on new seats (which I need).

Posted on: 2011/10/13 2:06

|

|

Transfer Transfer

|

||

Re: pulling the motor - question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

I got the bell housing off and I need a new clutch, it is worn almost to the rivets. I am hoping the flywheel is ok, anybody know how to tell for sure? Where can I get a good new clutch?

Posted on: 2011/10/7 23:11

|

|

Transfer Transfer

|

||

Re: pulling the motor - question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

Never did run the 1/4 but I did notice a nice boost in power with the hot cam and headers already. I am going with the local engine shop here in town. Is your new motor an LT1? What have you done to it? Did you build it yourself?

Posted on: 2011/10/7 3:27

|

|

Transfer Transfer

|

||

Re: pulling the motor - question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

I have found it almost impossible to find a crate LT1 so I am rebuilding mine.

Posted on: 2011/10/7 3:24

|

|

Transfer Transfer

|

||

Re: pulling the motor - question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

Thanks for the reminder, it's been a while since I had the hub off. I screw a longer 5/8" bolt in the hub to protect the threads while I put the puller on it to get it off.

Posted on: 2011/10/7 3:16

|

|

Transfer Transfer

|

||

Re: pulling the motor - question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

I need some help getting the bell housing off. It looks like in the FSM I need to loosen the "ball stud locking screw" right? Anything I need to look for with the clutch, throw out bearing wear and possible replacement?

Posted on: 2011/10/7 3:13

|

|

Transfer Transfer

|

||

Re: pulling the motor - question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Picture??

Posted on: 2011/10/6 22:08

|

|

Transfer Transfer

|

||

Re: pulling the motor - question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Motor is out!!! Now I see why some guys take the tranny out, then pull the motor. I wish I had pulled the hub and the balancer instead of just the balancer. It looks like getting this thing back in will be much harder than pulling it out. I had some free time at home today and just pulled it myself, wasn't too bad but not easy for sure. I'll post a pix.

Posted on: 2011/10/6 21:43

|

|

Transfer Transfer

|

||

Re: pulling the motor - question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

You guys are great!! I live in Brookfield, MO. 60 miles straight north on 63 to 36 hwy and then 35 mi west. It is 95 min from Columbia and 2 1/2hr from Jeff. That's pretty far to come. I have a buddy here coming to help me this weekend, the motor is totally stripped to just the bare block and I hope two hrs and it should be out, something always goes wrong though, we'll see. I'll keep you posted. Thanks man.

Posted on: 2011/10/6 14:46

|

|

Transfer Transfer

|

||

Re: pulling the motor - question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

Clam, thanks. How far did the motor have to come forward to release the bell housing from the tranny? I am thinking that I can raise the motor, remove the motor mounts, lower the motor back down, support the tranny, attach motor to the cherry picker to support it then I can reach the tranny to bell housing bolts, loosen and remove them and then slide the motor forward and up out of the engine bay with bell housing attached, sound good to you? I have the motor stripped down to just the bare block, that should help too.

Posted on: 2011/10/6 14:39

|

|

Transfer Transfer

|

||

pulling the motor - question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

I have read several forums on pulling the LT1 motor on my 93 vett. but still don't understand something. Several say to pull the tranny first (zf6spd) because the tranny and motor don't separate easily at the bell housing. If that is true then how is it easier to pull the tranny with the motor still in the car? It looks to me like unbolting the bell housing from the tranny, and pulling the motor and the bell housing together with the tranny in the car supported by a jack would work, am I missing something here?

If I am right, how far does the motor have to come forward to separate from the tranny before it can be lifted out of the engine bay?

Posted on: 2011/10/6 0:13

|

|

Transfer Transfer

|

||

Re: 93 LT1 rebuild question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

thanks guys! I am staying with the stock stroke, bored 30 over, stock rods, or maybe the Scat Qlite rods but 5.7 len for sure. I want to go with trick flow heads and think they will match my hot cam pretty well. These pistons; http://cgi.ebay.com/ebaymotors/Chevy- ... ories&hash=item4cfa02a6bf

Posted on: 2011/9/22 1:25

|

|

Transfer Transfer

|

||

Re: coolant air bleed pipe |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

The bolts were very corroded, the head of the bolts is slightly tapered, a 15mm works fine when the heads are off the motor (that's how I got mine off) but when on the block, impossible to get off. I am glad the dealer can still get them, hope that is still true.

Posted on: 2011/9/22 1:17

|

|

Transfer Transfer

|

||

Re: 93 LT1 rebuild question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Mic'd the valve guides and the valves, there is typically a .004-.005 difference between the two, the guides being worn that much bigger than the valve stem. That to me is pretty bad, I can't see why the machine shop guy here said the valve guides were fine? The piston skirts are typically .003-.004 smaller than the cyl bore which was .003 over, don't know what that translates into as far as way too much clearance or not.

Posted on: 2011/9/17 14:21

|

|

Transfer Transfer

|

||

Re: 93 LT1 rebuild question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Took #4 piston out, no broken rings but lots of crud around the sides of the piston and around the rings. The rod bearings are toast, full of scoring and a spot in the middle where it looks like the surface is completely worn away. Putting the valves back in the guides I can wiggle them a bunch, it seems to me that there should be almost no play if the valves and guides were in spec?

The intake is completely black inside but not oily. It's more like carbon deposits, gritty and dry (from the EGR?) Cylinder #4 has a big galled spot, it looks very strange and very smooth. I'll try to get some more pix soon. Still have not figured out the download for pix yet.

Posted on: 2011/9/16 1:17

|

|

Transfer Transfer

|

||

Re: 93 LT1 rebuild question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

No it wasn't, it did have a coating of oil though. The PCV on the LT1 actually attaches to a bung on the intake, the hose looks like a U shape, one part of the U attaches to the PCV valve the other to the intake bung. I don't know where it vents, but it is inside the intake somewhere. Maybe some will chime in who knows more about the PVC and how it works on the LT1 and how it might pull oil into the intake. Would oil coming in the PCV puddle on the closed intake valve? There was oil in the TB though, and in the tube that comes from the valve cover to the TB, for oil to get all the way back to the TB when there should be only vacuum there must mean that pressure in the crank case must of overcome the vacuum from the PCV valve right?

Posted on: 2011/9/15 3:57

|

|

Transfer Transfer

|

||

Re: 93 LT1 rebuild question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Thanks for all the help. I took the heads to the machine shop here in town, he said he couldn't see how that much oil could get thru the guides, he thought they were not that lose. He also let me use this bore gauge to check for taper and out of round. The worst cylinders were out of round .0015, taper was at the worst .0020, he said that by itself would not allow that much oil either, unless a ring was stuck. I will try to get the pistons out soon and see what the rings look like. If that much oil is getting in the cylinders but not thru the rings or guides how could it get there?

Posted on: 2011/9/15 3:17

|

|

Transfer Transfer

|

||

Re: 93 LT1 rebuild question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

crap I thought pictures would appear, sorry!!

Posted on: 2011/9/14 16:40

|

|

Transfer Transfer

|

||

Re: 93 LT1 rebuild question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

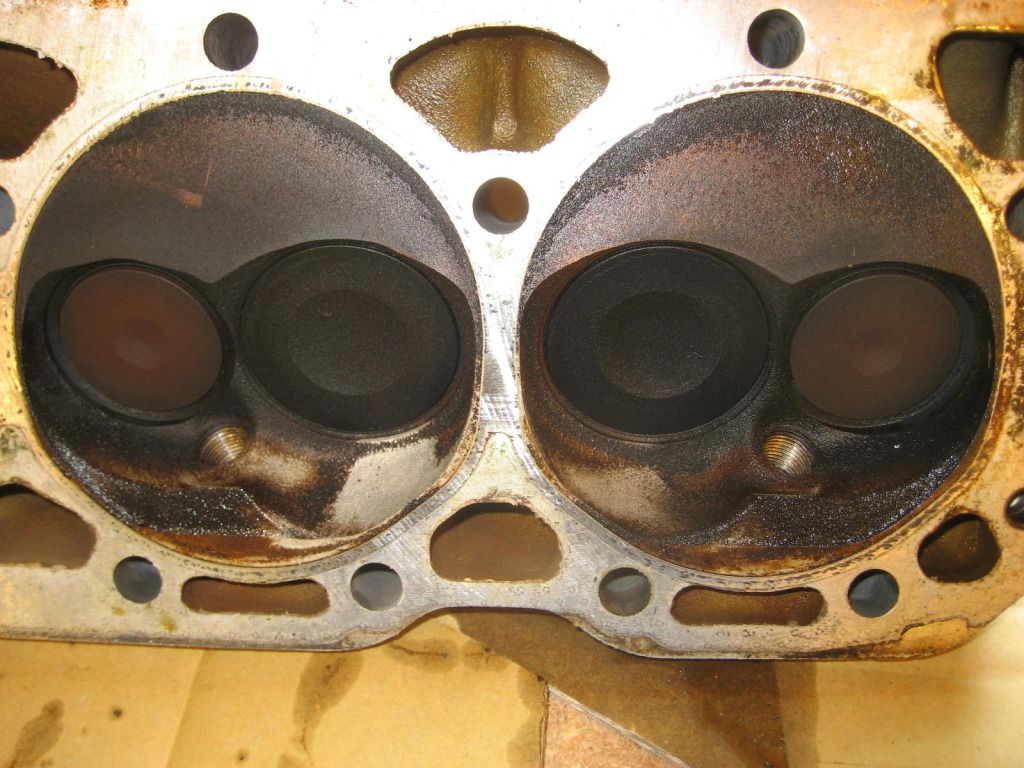

Here are some pix of the cyl. bores, they look pretty good to me. The motor turns over very easy so I think there are no spun bearings? The valve guides look like oil has been running down them. The valve seals, when I took them off were full of oil? What about this piston? http://www.summitracing.com/parts/UEM-KB231-030/ it would bump the compression up to about 10.8 to one from the stock 10.4 with only two valve reliefs that is about where the LT4 is, would there be problems with that?

Posted on: 2011/9/14 16:39

|

|

Transfer Transfer

|

||

Re: 421 dyno |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

VERY nice, you work so hard and now you reap the reward! You just need a good set of drag radials, nice problem to have.

Are you using the stock computer or something else?

Posted on: 2011/9/13 13:22

|

|

Transfer Transfer

|

||

Re: 93 LT1 rebuild question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

PS what should I be looking at with main and rod bearing clearance?

Posted on: 2011/9/11 14:43

|

|

Transfer Transfer

|

||

Re: 93 LT1 rebuild question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

Thanks man, I will measure the cyl bores tomorrow and hopefully pop the springs too. It is much harder for me to remove the springs now that the heads are off, I will have to take them to the machine shop here to have that done. Am I right in assuming that the guides are shot because I have oil puddling on the valves that are closed? I can't figure out how that oil got there unless it leaked down the guide after the motor was shut off??

Posted on: 2011/9/11 14:42

|

|

Transfer Transfer

|

||

Re: Pulling the engine on a 92 LT1 6spd manual |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Quote:

Are you pulling the engine for a rebuild? If so what are you thinking in that direction? I will be pulling mine soon and need to do a rebuild and am trying to learn all I can before I start.

Posted on: 2011/9/11 14:36

|

|

Transfer Transfer

|

||

Re: 93 LT1 rebuild question |

||

|---|---|---|

|

Senior Guru

Joined:

2010/8/20 19:44 From missouri

Posts:

250

|

Valve guides are shot. I just got the heads off and I can still see cross hatch in most of the cylinders. It was #4 that had a leak down rate of 23% Actually that cyl. looks pretty good too but the rings must be bad, not really sure? I assume the crank is fine, I am sure I did not spin a bearing, the engine turns over fine and runs fine, just started using a ton of oil.

Posted on: 2011/9/9 21:29

|

|

Transfer Transfer

|

||

IMG_4224.JPG (31.36 KB)

IMG_4224.JPG (31.36 KB)