|

|

Register To Post |

| 1990 L98 rebuild | |||

| Guest_ |

Thank you to the forum for allowing me to join and post this message. I hope I can be some help to others who are looking for an answer.

My car is a one owner convertable/ hard top. I like to drive it like I stole it at times or just cruise with the top down. It has AC, new radiator, and is an unmolested survivor until now. I am rebuilding my 1990 L98 after the # 7 head gasket finally let go. It only had 190,000 miles on it. I would like to hear your thoughts and advise on my build. What kind of numbers do you think it will make. I am building this engine for torque. I have never liked spinning one at high RPM for top speed, but I like acceleration and mid range power. I'm keeping the TPI and I rarely ever turn it over 5,000 RPM. I have all new internals - Scat crank, new cast pistons, Custom GM shot peened LJ rods,new roller lifters, reworked 113 heads- .008 shaved, 1010 Felpro head gaskets, alighn bored mains, decked .010, honed with the torq plate, new timing set, true dules with H-pipe. I have new Bosch III injectors from Jon. New OE style melling Oil pump and mellonized distributor gear. THe only internal parts that I'm using from the origional engine are the push rods and the lifter spider. Here is the Howards cam specs.: HRS-180225-12 Cam Style:Hydraulic roller tappet Basic Operating RPM Range:800-4,200 Intake Duration at 050 inch Lift:207 Exhaust Duration at 050 inch Lift:213 Duration at 050 inch Lift:207 int./213 exh. Advertised Intake Duration:260 Advertised Exhaust Duration:262 Intake Valve Lift with Factory Rocker Arm Ratio:0.450 in. Exhaust Valve Lift with Factory Rocker Arm Ratio:0.465 in. Valve Lift with Factory Rocker Arm Ratio:0.450 int./0.465 exh. Lobe Separation (degrees):112 I have the Auto Trans in Bossier City, LA - it's a PATC Raptor 700 hooked to a 2400 stall converter. This is one stout 700R4. Stock 2.59 rear gear. It pulls like crazy to 5000 RPM and the stock engine never dropped below 3000 RPM when it shifted during the hammer down sessions. I'm looking forward to wringing this engine out after it gets broke in. |

||

Posted on: 2012/11/2 14:09

Edited by red90 on 2012/11/2 14:30:29 Edited by red90 on 2012/11/2 15:01:52 |

|||

Transfer Transfer

|

|||

| Matatk | Re: 1990 L98 rebuild | ||

|

Webmaster

|

Welcome to the forum! Sounds like everything you are doing is right on the money. As far as the cam selection, I am no expert. Hopefully one of our members, perhaps Will or David, can chime in soon on that topic.

Matthew |

||

Posted on: 2012/11/2 14:46

|

|||

|

_________________

2002 EBM convertible, Magnusson supercharger, cam, headers, etc. 1989 Corvette...RIP |

|||

Transfer Transfer

|

|||

| bogus | Re: 1990 L98 rebuild | ||

|

Grand Imperial Pooh-Bah

|

a small detail... there is no such thing as a "hyrdraulic roller tappet" lifter, it is either a flat tappet or hydraulic roller.

All L98s from 1986, with aluminum heads, have roller lifters. Heads? Are you porting stock or what? Leaving them stock won't help. Intake/exhaust mods? |

||

Posted on: 2012/11/2 15:28

|

|||

|

_________________

The single biggest problem with communication is the illusion that it has taken place. - George Bernard Shaw Education is the best tool to overcome irrational fear. - me |

|||

Transfer Transfer

|

|||

| Re: 1990 L98 rebuild | |||

| Guest_ |

Thanks for the replies. The bowls and runners are cleaned up a little with sandpaper & sanding wheels, but the port size is the same dimensions as they came from the factory. I'm using the factory tubular exhaust manifolds. I ground the openings to match the D-ports as close as I could. Those manifold ports are made of some tough steel. I'm hoping the true duel pipes with the H-pipe will work better than the stock system. Any thoughts on the cam choice? I did'nt want to make an all out screamer of an engine. I just want a reliable engine with torque. I will never take the car down the track. I'm keeping the TPI intact with new Bosch III from Jon.

|

||

Posted on: 2012/11/2 15:52

Edited by red90 on 2012/11/2 16:08:40 |

|||

Transfer Transfer

|

|||

| Matatk | Re: 1990 L98 rebuild | ||

|

Webmaster

|

I would dump the exhaust manifolds for some real headers. Also are you having a tune done for the upgrades? That's the best way to maximize you upgrades. I believe the 1990s went to speed density from MAF? From what I'm told the SD is not as forgiving of major mods like MAF. As far as injectors, are you going to 24 or 26 lbs?

|

||

Posted on: 2012/11/2 17:46

|

|||

|

_________________

2002 EBM convertible, Magnusson supercharger, cam, headers, etc. 1989 Corvette...RIP |

|||

Transfer Transfer

|

|||

| Re: 1990 L98 rebuild | |||

| Guest_ |

The injectors I got from Jon at FIC are the stock size for a 1990 350. I'm not sure if they are 22 lb. or 24lb. I'm sure headers would be nice. I didn't have them in my budget ( headers and exhaust pipes)and my mostly stock set up wouldn't gain much.

Again, I am aiming for torque, not wide open HP. I know that I'm not building the high RPM screamer that some like. I just want an engine that compliments what the TPI does well and that is make torque. Most of the bolt on speed parts are compromised by the weakest link on the engine. I did not want to sink over $ 3500 in this car. The engin I built has @ $2400 in parts, machine work and labor. It does not take long to exceed that $$ amount. The original engine had pleanty of speed for the roads around here. There is not many places to open one up for more than a 1/4 mile before you have a curve, intersection or barking dog in the road. Thank you for the response. I just thought I would share this project with the Gurus. I hope others can read and gain a little bit of knowledge. Not every car is going to be built to the max. This is a build that will keep me on the road. One think I have learned, no matter how much you think you will spend on building an engine, you had better make provisions to double that figure. |

||

Posted on: 2012/11/2 18:30

|

|||

Transfer Transfer

|

|||

| Matatk | Re: 1990 L98 rebuild | ||

|

Webmaster

|

Barry - I agree with you that not every rebuild has to be taken to the max! I certainly went overboard with mine and time and money can get way out of hand with these things. Having a reasonable goal like you do is extremely important in these things. I was just suggesting headers since you've already come this far. Perhaps in another year once things settle down you might consider them. They will only complement everything else you've done already.

I am concerned the 22 lb injectors might not be enough for your build. 24s would probably be more appropriate. Check here for a little online calculator: http://www.rceng.com/technical.aspx A 300 hp (estimate) build with .50 brake specific fuel consumption at 43.5 psi would be 23.57 lb/hr injectors. Also, since you are keeping the stock TPI I would recommend spending a few hours with a grinder and porting and cleaning up the intake base, runners, and plenum. Won't be worth a ton of hp, but if you've got the time it's worth it. Matthew |

||

Posted on: 2012/11/2 19:14

|

|||

|

_________________

2002 EBM convertible, Magnusson supercharger, cam, headers, etc. 1989 Corvette...RIP |

|||

Transfer Transfer

|

|||

| Matatk | Re: 1990 L98 rebuild | ||

|

Webmaster

|

And do you plan on having it tuned? PCM4less is a well known tuner for our cars.

|

||

Posted on: 2012/11/2 19:15

|

|||

|

_________________

2002 EBM convertible, Magnusson supercharger, cam, headers, etc. 1989 Corvette...RIP |

|||

Transfer Transfer

|

|||

| rklessdriver | Re: 1990 L98 rebuild | ||

|

Senior Guru

|

The Howards PN 110225 camshaft you have listed is pretty much a stock replacement cam.

It will work fine, however I feel the PN 110235-12 will provide a bunch more power from 2500-5000 and not give anything up below 2500rpm... Espc with the converter you have. I doubt the stock pushrods are going to be the right length with you changing to an aftermarket cam, lifters and rockers. If your going to grind on the heads - At least do something that will help... With the intake valve being 1.94" you need to port the valve bowl to a dia of 1.760" minimum which is 90% of the valve size/area.... the exhaust should be 85% of 1.50" which is 1.20".... When the machinist does the valve job on the heads, on the intake I'd suggest 65* throat, 45* seat (0.060 wide), and 27* top cut all the way to the casting/combustion chamber.... On the exhaust 60* throat, 45* seat (.080 wide) and 30* top cut. Also make sure he back cuts the intake valve @ 30* all the way to the seat angle. No back cut on the exhaust valve. The dual exhaust is one of the best things you can do for a TPI Corvette... The Y-Pipes and single main converter suck for making power. Try to find a 3.07 rear end... It works really well with the 700R4 and TPI powerbands... The 2.59 is going to drag it down against the converter something horrible on the 1-2 shift. Will |

||

Posted on: 2012/11/2 19:51

|

|||

|

_________________

1984 Corvette. 434 SBC with a Powerglide. Best pass - 8.48@160MPH 1.23 60ft on MT 275/60R15 Radials. 1972 Corvette. LS5 454 BBC with M20 4 speed. Best Pass - Doing good to just pass a gas station. |

|||

Transfer Transfer

|

|||

| flyboy | Re: 1990 L98 rebuild | ||

|

Elite Guru

|

True duals, a small bump in compression, warmer than stock cam, and a some cylinder head clean up. Hopefully you'll have a nice little bump up in power from stock. Is the engine together already?

|

||

Posted on: 2012/11/2 23:35

|

|||

|

_________________

'91coupe, LT4Hotcam, some other stuff. If it's too loud, you're too old. "He works on old cars, then junks 'em" |

|||

Transfer Transfer

|

|||

| Re: 1990 L98 rebuild | |||

| Guest_ |

Thanks for all of the comments. The short block is put together. The heads are reworked and assembeled. It is too late to do anything to the ports and bowls. I will see what I can do on the intake base and clean it up a little more than the factory casting allowed. I'm going to do the 3.07 rear gear when I change the rear bushings. This cam has a little more lift and duration than the 1990 factory cam. I will get the tune from Alvin @PCM..... Why do ya'll think the # 7 cylinder is always the problem? Did GM ever acknowlege the problem and correct things? |

||

Posted on: 2012/11/4 14:34

|

|||

Transfer Transfer

|

|||

| Ultraman | Re: 1990 L98 rebuild | ||

|

2015 Memorial Day Car Show Winner!

|

I was heading in the same direction as you are with my 90. I was hoping to get around a 300 crank hp by cleaning up the intake and the exaust. I have been trying to find my dyno posts but so far can't. I did find the post that showed my header and exaust work.

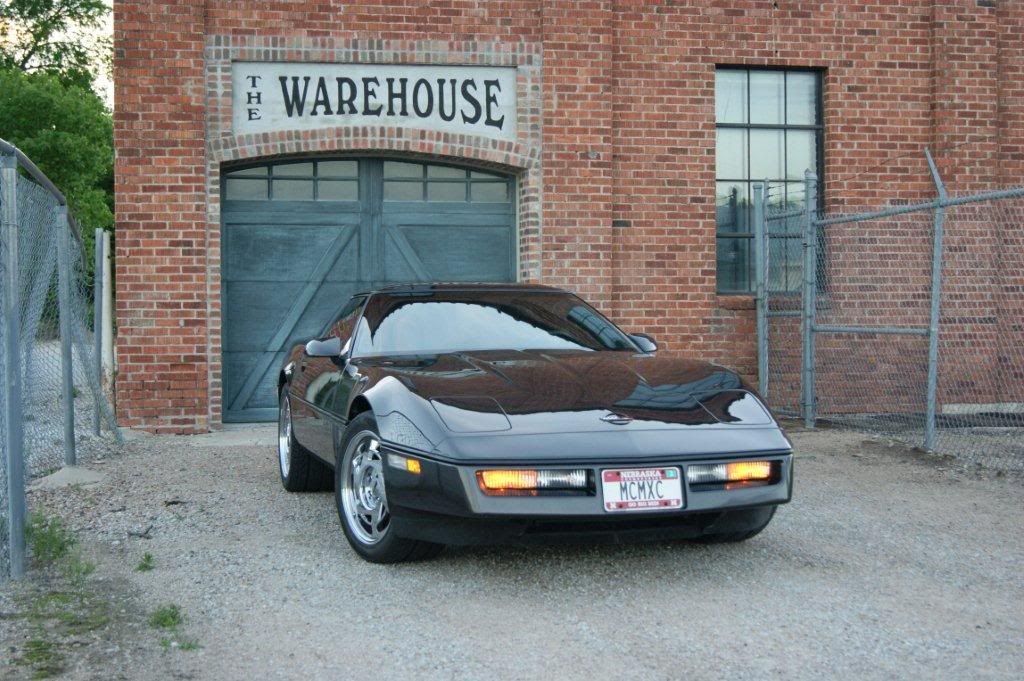

If I recall the stock base line dyno was 194 hp and after the exhaust mods we were at 214 rwhp and torque was up also....that's from memory...its been awhile back. My next move was to clean up the top end with a set up like Matt just took off and see if I couldn't add another 20 rwhp. Then this C5 came along and then this C6 so I never got to finish the project.....good luck with yours... http://www.corvetteguruforum.com/modu ... id=160947#forumpost160947 I did find the pics of the dyno tests...first is stock  after the exhaust work....  Here is a pic of the car....it had the 3.07's in it...it was a great C4....  |

||

Posted on: 2012/11/4 15:04

|

|||

|

_________________

2010 Grand Sport Coupe Gone but not forgotten... Vote DeSantis in 2024.... Make the IRS go away... |

|||

Transfer Transfer

|

|||

| Matatk | Re: 1990 L98 rebuild | ||

|

Webmaster

|

Quote:

From what I've read, #7 and #8 run hotter because the way the coolant flows through the system and it gets to those last. Could it also be due to the fact that the block is against the fire wall and has less heat dissipation? Or timing/spark related? On the stock L98 gaskets you'll see a blocked port on the back of the intake ports for those cylinders. I guess GM thought if they restricted the flow there, the coolant would remain longer and cool better? I've also read that GM finally addressed the head gasket issue at the end of the L98 run, around 1991, and the ZZ3 crate motors use the revised head gasket. But I can't find any proof/tsb/etc on this. Matthew |

||

Posted on: 2012/11/4 22:17

|

|||

|

_________________

2002 EBM convertible, Magnusson supercharger, cam, headers, etc. 1989 Corvette...RIP |

|||

Transfer Transfer

|

|||

| Re: 1990 L98 rebuild | |||

| Guest_ |

Thanks for the numbers on your Dyno run. I hope that this build and modifications increase the G force. I am an acceleration freak. I have been that way since a ride in a '71 Buick GS. It had over 500 lbs. of torque. It would launch like a rocket. This Corvette is lighter, lower and has better center of gravity and front to rear weight ratio. It will be whatever it is when I get finished. I will post some pictures. This car looks better than most cars under 50K miles. It is not your typical 190,000 mile car. Everything works and when something needs R & R, it gets done. I would not hesitate to drive it on any long trip.

|

||

Posted on: 2012/11/5 14:16

|

|||

Transfer Transfer

|

|||

| rklessdriver | Re: 1990 L98 rebuild | ||

|

Senior Guru

|

Quote:

Cyl 7&8 get water last in the **block** but that dosen't have anything to do with it.... The real heat for the cooling system is in the cyl heads (combustion chamber), not the block... If heat was the real problem, then cyl 1&2 would be blowing, since they are the last to cool... In the bigger picture.... Don't forget about the 2 exhaust valves situated right next to each other in cyls 3&5 and 4&6..... That is some real heat and can be a real problem on some racing engines.... which we mitigate with external cooling lines. Around cyl 7&8 is where the coolant is forced up to the cyl heads... that is the point of greatest restriction and water pressure..... also when you shut the engine off, water drains back to that point and coolant system sediment settles there... That is where corrosion comes into play.... Most head gasket failures on L98's, I've seen are a product of corrosion, due to a lack of cooling system maintenance. A little corrosion there, couple with the higer water pressure is why I think most all head gaskets fail in that area. Will |

||

Posted on: 2012/11/5 20:04

|

|||

|

_________________

1984 Corvette. 434 SBC with a Powerglide. Best pass - 8.48@160MPH 1.23 60ft on MT 275/60R15 Radials. 1972 Corvette. LS5 454 BBC with M20 4 speed. Best Pass - Doing good to just pass a gas station. |

|||

Transfer Transfer

|

|||

| Re: 1990 L98 rebuild | |||

| Guest_ |

That makes sense. That is probably why the LT engines have the reverse cooling through the heads. Thank you for the information. Smokey yunick used to put a little Ivory dish detergent in his cooling systems to eliminate the static tension of the water on the metal surfaces in the cooling chambers. Claimed it helped the cooling throug out the engine.

|

||

Posted on: 2012/11/5 21:32

|

|||

Transfer Transfer

|

|||

| corvetteronw | Re: 1990 L98 rebuild | ||

|

Senior Guru

|

Hey Red - welcome to the Guru!

Interesting. I just logged on to Comp Cams website and filled out their cam request form for my 91 A4 coupe. I have somewhat the same goals as yourself. They are supposed to get back to me within 2 business days as to what they recommend. Here is my winter project (some of the choices are due to budget constraints as I don't want to dump too much cash in to something I plan to sell next summer). Engine has about 110,000 miles. I too am staying with the 113 heads and planning on having them rebuilt with some mild porting along with cutting them down a tad. I was going to go with some stamped steel roller tip rockers. The intake has a mildly ported plenum, Accel runners matched to the plenum and mildly ported base. I have new Bosch IIIs from Jon along with a high performance distributor and adjustable fuel pressure regulator. I think I am going with the shorty ceramic headers from McJacks that will bolt right up to my emissions system and attach to the new front catless Y that is on there now. McJack says they are ported to match the stock L98 heads. I also have a Magnaflow high flow cat along with a H-pipe rear Y and Magnaflow mufflers. The car has the G92 performance axle and a stock A4 and torque converter. I have the FX3 system (looks like 1 of the adjusters just went bad!) along with the No Flex frame braces from Vette2Vette. I know that I could get more power with long tubes, dual exhaust, aftermarket heads, Super Ram and a better torque converter - BUT - the budget rears its nasty head once again. I will copy and post the cam recommendation that I get from COmp Cams as it may be of some interest to you. |

||

Posted on: 2012/11/8 3:44

|

|||

|

_________________

A VETERAN IS SOMEONE WHO AT ONE POINT WROTE A BLANK CHECK MADE PAYABLE TO THE UNITED STATES OF AMERICA FOR AN AMOUNT OF UP TO AND INCLUDING THEIR LIFE. |

|||

Transfer Transfer

|

|||

You can view topic.

You cannot start a new topic.

You cannot reply to posts.

You cannot edit your posts.

You cannot delete your posts.

You cannot add new polls.

You cannot vote in polls.

You cannot attach files to posts.

You cannot post without approval.

|

|