|

|

Register To Post |

| bam | 93 LT1 rebuild question | ||

|

Senior Guru

|

My 93 LT1 vett motor went south after a hot cam install. I am looking at this rotating assy. (http://www.jegs.com/i/Eagle/356/B1340 ... -1?parentProductId=763943) Any comments? It is balanced so will I be able to use it with my 6 speed tranny? The 6 speed has a flywheel with the teeth in it for the starter and not a flexplate right? I called Jegs and they said this will will work with my tranny but I just want to double check. I am also looking at trick flow 180 heads.

When removing the heads I pretty much destroyed the coolant air bleed pipe anyone know where I can get a new one or at least the rubber stuff that seals it to those bolts that go into the water jacket in the head? Thanks |

||

Posted on: 2011/9/9 18:37

|

|||

Transfer Transfer

|

|||

| bogus | Re: 93 LT1 rebuild question | ||

|

Grand Imperial Pooh-Bah

|

A mantra preached to me... don't trust their balancing jobs.

And yes, you will be able to use the 6spd. You will just need to get either a new flywheel or reuse the dual mass. Flexplates are used with automatics. Your best bet is to get the unit internally balanced, then get a neutral balanced flywheel and be done with it. I don't know much about that rotating mass, but it is a bottom feeder... doesn't impress me much. |

||

Posted on: 2011/9/9 19:58

|

|||

|

_________________

The single biggest problem with communication is the illusion that it has taken place. - George Bernard Shaw Education is the best tool to overcome irrational fear. - me |

|||

Transfer Transfer

|

|||

| rklessdriver | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

What broke in the stock LT1?

That Eagle kit is cast crank, SIR rods and cast/Hyper pistons.... not really any better than the stock parts. The Speed Pro pistons use old style 5/64/3/16 rings instead of the meteric 1.5/3mm, rings the stock LT1 uses.... You'd be better off reusing the stock/factory crank and rods if you can and buying a set of Speed Pro H669ACP30 pistons which have the thinner meteric 1.5/3mm rings. If it burned up the crank or spun a bunch of rods, then that Eagle kit would be an OK replacement. The Eagle kit is balanced to use the stock counterweight FW and neutral harmonic balancer.... Just like stock. I'd say 99% of the time the balance Eagle does is fine to use out of the box on a low HP engine like a Hot cam. Sure they do screw some up but so did GM - how many LTX's have extra weight pushed in the balancers and FW's..... At any rate tell us what all is screwed up in your LTX and maybe we can give you some better part recomendations to build it up right. Will |

||

Posted on: 2011/9/9 20:43

|

|||

|

_________________

1984 Corvette. 434 SBC with a Powerglide. Best pass - 8.48@160MPH 1.23 60ft on MT 275/60R15 Radials. 1972 Corvette. LS5 454 BBC with M20 4 speed. Best Pass - Doing good to just pass a gas station. |

|||

Transfer Transfer

|

|||

| bam | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

Valve guides are shot. I just got the heads off and I can still see cross hatch in most of the cylinders. It was #4 that had a leak down rate of 23% Actually that cyl. looks pretty good too but the rings must be bad, not really sure? I assume the crank is fine, I am sure I did not spin a bearing, the engine turns over fine and runs fine, just started using a ton of oil.

|

||

Posted on: 2011/9/9 21:29

|

|||

Transfer Transfer

|

|||

| rklessdriver | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

Quote:

You got alot of options man. No reason to throw away perfectly good rods and crank only to replace it with something that is not any better. If you want to put it back with the that level of parts then buy the Speed Pro's I gave you the PN to (Jegs sells them a kit PN 884-8KH669ACP30, with pistons and rings for like $340). Have your crank/rods checked out, new rod/main brgs, clean the block, bore/hone the block, new core plugs and cam brgs. You'll be better than the stock bottom end if you set the rod and man clearance up right (IMO the biggest weakness in the stock LTX). The Mahle 224-3497 is another option thats a bit cheaper. ($205 on ebay).. In fact it's the same piston GM used stock. This guy on ebay is selling them as a kit w/rings in any oversize. http://cgi.ebay.com/ebaymotors/Chevy- ... ories&hash=item4cfa02a6bf Will |

||

Posted on: 2011/9/9 23:44

|

|||

|

_________________

1984 Corvette. 434 SBC with a Powerglide. Best pass - 8.48@160MPH 1.23 60ft on MT 275/60R15 Radials. 1972 Corvette. LS5 454 BBC with M20 4 speed. Best Pass - Doing good to just pass a gas station. |

|||

Transfer Transfer

|

|||

| flyboy | Re: 93 LT1 rebuild question | ||

|

Elite Guru

|

I know you did the leak down test but did you come to any concrete conclusions where the leak was? You say the bore looks good? I'd hate to tear down the motor if it's not really necessary, not that it hasn't been done before.

|

||

Posted on: 2011/9/10 3:24

|

|||

|

_________________

'91coupe, LT4Hotcam, some other stuff. If it's too loud, you're too old. "He works on old cars, then junks 'em" |

|||

Transfer Transfer

|

|||

| Matatk | Re: 93 LT1 rebuild question | ||

|

Webmaster

|

Listen to Will. That's my advice

If I had to do it over again...cost wise it would be stock crank, polished stock rods, .30 pistons, cam, heads. Your LT1 heads are already pretty good, might consider a mild port/polish job with bowl work. It's easy to go way overboard with a rebuild...spend wisely. Matthew |

||

Posted on: 2011/9/10 11:33

|

|||

|

_________________

2002 EBM convertible, Magnusson supercharger, cam, headers, etc. 1989 Corvette...RIP |

|||

Transfer Transfer

|

|||

| BillH | Re: 93 LT1 rebuild question | ||

|

The Stig Moderator

|

Quote:

23% isn't the rings unless they are totally stuck. You need to pop the springs on #4 and check for a bent valve or carbon build up. I've seen carbon buildup blow a leakdown test before. Then you need to bore gauge the cylinders to check for out of round and cylinder taper. And the amount of ridge at the top of the cylinder. This will determine what you need to do and should be done before even considering what to buy. After that, listen to Will's advice. |

||

Posted on: 2011/9/10 12:29

|

|||

|

_________________

Every man dies but not every man lives. |

|||

Transfer Transfer

|

|||

| bam | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

Quote:

Thanks man, I will measure the cyl bores tomorrow and hopefully pop the springs too. It is much harder for me to remove the springs now that the heads are off, I will have to take them to the machine shop here to have that done. Am I right in assuming that the guides are shot because I have oil puddling on the valves that are closed? I can't figure out how that oil got there unless it leaked down the guide after the motor was shut off?? |

||

Posted on: 2011/9/11 14:42

|

|||

Transfer Transfer

|

|||

| bam | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

PS what should I be looking at with main and rod bearing clearance?

|

||

Posted on: 2011/9/11 14:43

|

|||

Transfer Transfer

|

|||

| BillH | Re: 93 LT1 rebuild question | ||

|

The Stig Moderator

|

Quote:

Well Tom, assumptions never work out. The only way to find out is to measure the guides. And since you're taking it to the shop anyway, get them to inspect everything. Then you'll be sure. It's just the way it has to be done. |

||

Posted on: 2011/9/11 14:55

|

|||

|

_________________

Every man dies but not every man lives. |

|||

Transfer Transfer

|

|||

| BillH | Re: 93 LT1 rebuild question | ||

|

The Stig Moderator

|

Quote:

Crank main #1 0.0007 - 0.0021 #2,3,4 0.0009 - 0.0024 #5 0.0010 - 0.0027 BUT there is also a "Service Limit" spec Rods - 0.0013 - 0.0035 And clearance is not the only thing to check on a crank, out of round, taper, etc. This is also a thing for a machine shop to check. |

||

Posted on: 2011/9/11 15:01

|

|||

|

_________________

Every man dies but not every man lives. |

|||

Transfer Transfer

|

|||

| flyboy | Re: 93 LT1 rebuild question | ||

|

Elite Guru

|

[quote]

bam wrote: [quote] It is much harder for me to remove the springs now that the heads are off, I will have to take them to the machine shop here to have that done. I would take BillH's advice and have a machine shop check the heads. Maybe you'll find the problem there and save yourself a lot of time, energy, and money. Of course, if you are intent on an engine rebuild/upgrade, go for it and good luck. |

||

Posted on: 2011/9/11 15:49

|

|||

Transfer Transfer

|

|||

| rklessdriver | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

Quote:

When it goes back together: You want to set the rods at .002 and the mains at .0020-.0025 The factory typical is around .0013-.0015 rods and very tight .001 (mains)... sometimes less. That will NOT make it once you go near 400HP and start turning the motor over 5500RPM on a regular basis. Will |

||

Posted on: 2011/9/11 17:03

|

|||

|

_________________

1984 Corvette. 434 SBC with a Powerglide. Best pass - 8.48@160MPH 1.23 60ft on MT 275/60R15 Radials. 1972 Corvette. LS5 454 BBC with M20 4 speed. Best Pass - Doing good to just pass a gas station. |

|||

Transfer Transfer

|

|||

| bam | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

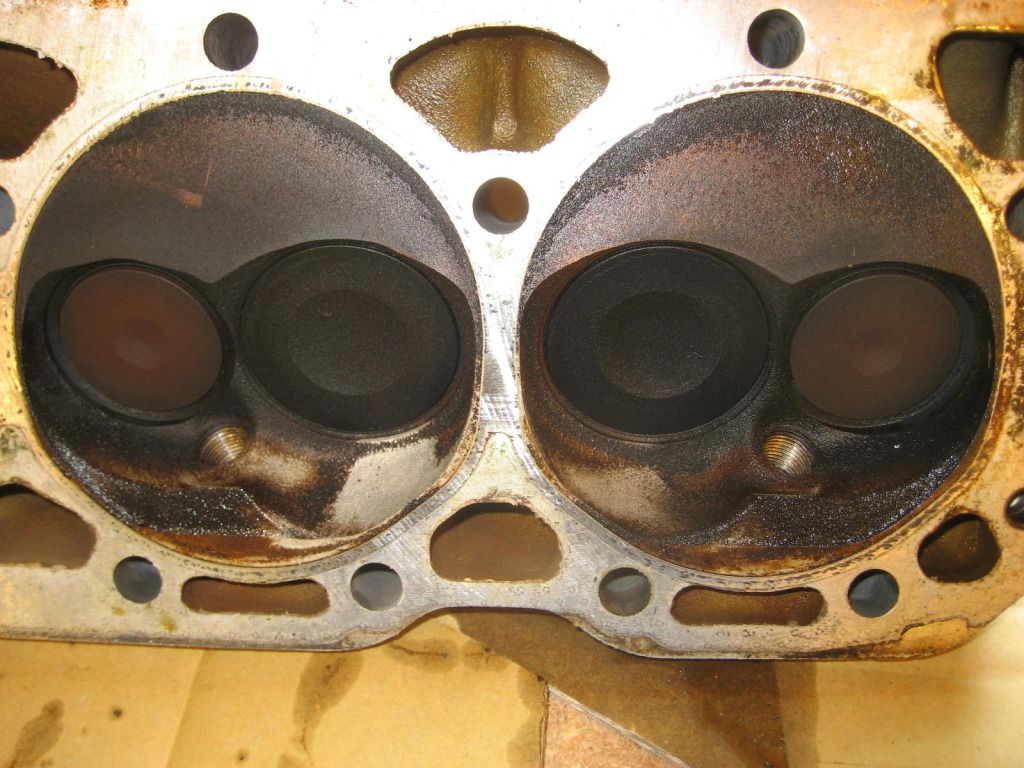

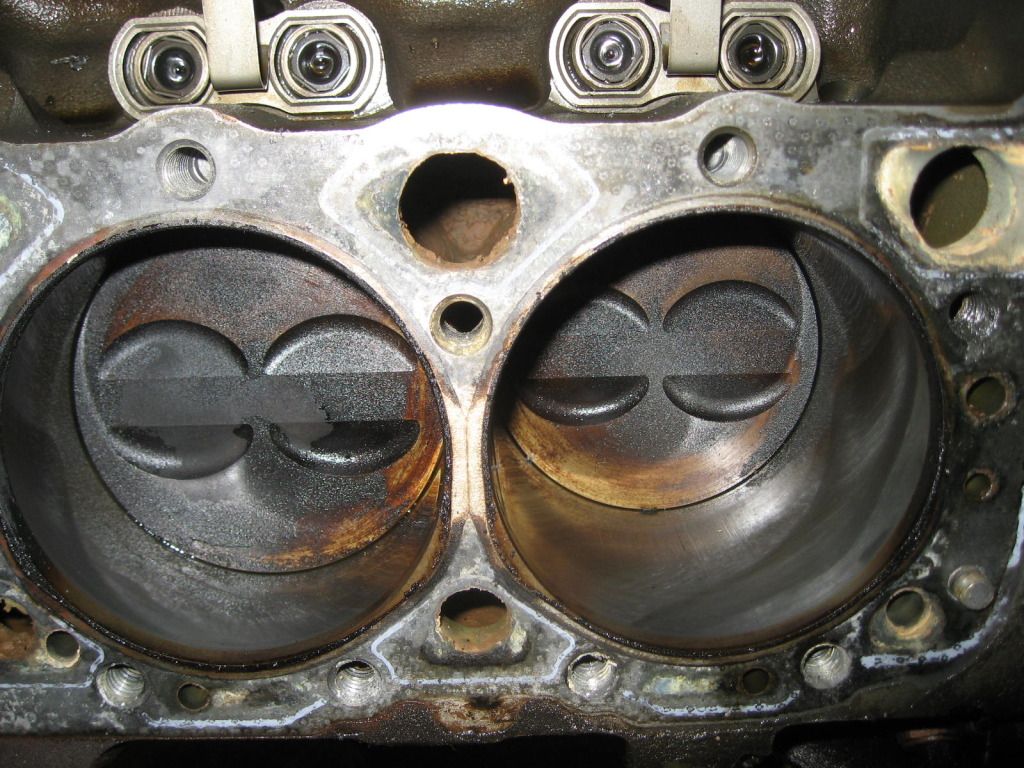

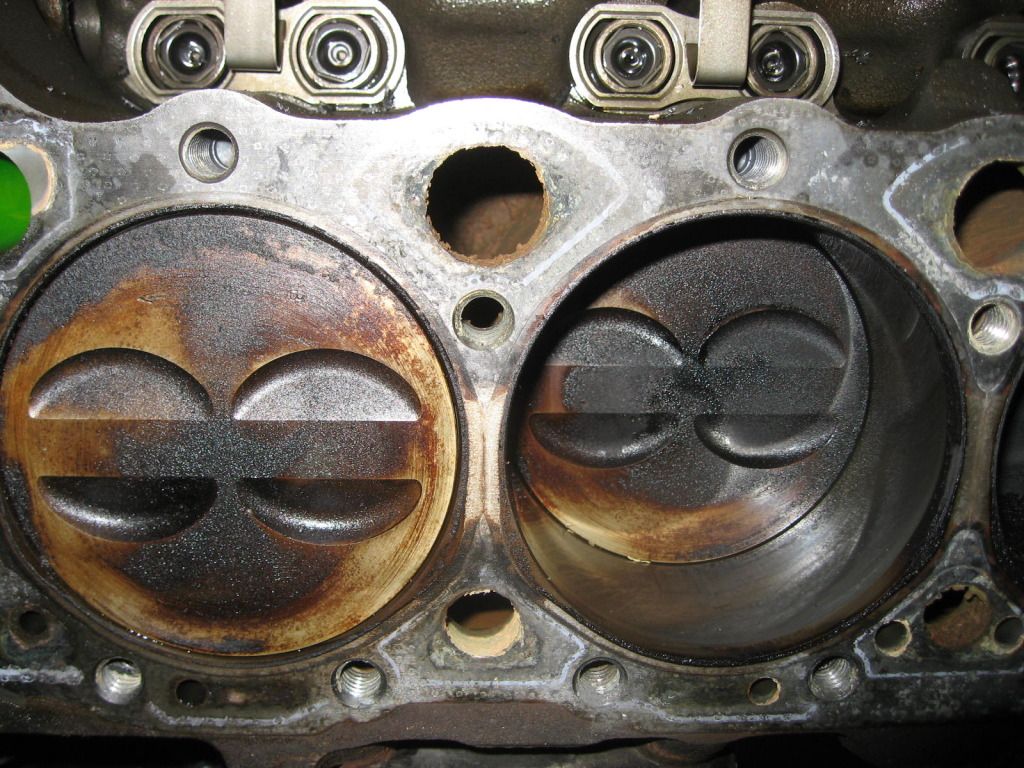

Here are some pix of the cyl. bores, they look pretty good to me. The motor turns over very easy so I think there are no spun bearings? The valve guides look like oil has been running down them. The valve seals, when I took them off were full of oil? What about this piston? http://www.summitracing.com/parts/UEM-KB231-030/ it would bump the compression up to about 10.8 to one from the stock 10.4 with only two valve reliefs that is about where the LT4 is, would there be problems with that? |

||

Posted on: 2011/9/14 16:39

|

|||

Transfer Transfer

|

|||

| bam | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

crap I thought pictures would appear, sorry!!

|

||

Posted on: 2011/9/14 16:40

|

|||

Transfer Transfer

|

|||

| Matatk | Re: 93 LT1 rebuild question | ||

|

Webmaster

|

Quote:

I took care of it for you. When you use photobucket, just use the "html" code for the picture  |

||

Posted on: 2011/9/14 17:07

|

|||

|

_________________

2002 EBM convertible, Magnusson supercharger, cam, headers, etc. 1989 Corvette...RIP |

|||

Transfer Transfer

|

|||

| rklessdriver | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

That is a lot of oil burning to be just guides.....

There is alot of corrosion around the water jacket on the end cyl as well and it looks like it was pushing out the fire ring right there. Be sure to get the heads surfaced.... The KB 231 will work but it uses 1/16" rings and those rings can be expensive.... not to mention they were the standard for racing engines for many, many yrs and you have to be careful which set you use on the street. I personally really like to use the Perfect Circle 315-0036 ($90.00) but it's a file fit ring set. Something like the Hastings CM5532 ($69.00) would be a good ring for the street and not file fit.... but with KB hyper pistons you will still have to open the top ring gap up some..... Your gonna spend more $$$ than the Mahle piston/Ring deal on ebay I showed you... and you really not going to gain any compression because KB uses a HUGE trough type valve relif that is 6cc's (the same cc as the 4 small valve relifs in the Mahle piston). The smart way to gain compression is by using the Victor Reinz 5898 head gasket and milling the heads down to 52cc's..... Will |

||

Posted on: 2011/9/14 20:49

|

|||

|

_________________

1984 Corvette. 434 SBC with a Powerglide. Best pass - 8.48@160MPH 1.23 60ft on MT 275/60R15 Radials. 1972 Corvette. LS5 454 BBC with M20 4 speed. Best Pass - Doing good to just pass a gas station. |

|||

Transfer Transfer

|

|||

| bam | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

Thanks for all the help. I took the heads to the machine shop here in town, he said he couldn't see how that much oil could get thru the guides, he thought they were not that lose. He also let me use this bore gauge to check for taper and out of round. The worst cylinders were out of round .0015, taper was at the worst .0020, he said that by itself would not allow that much oil either, unless a ring was stuck. I will try to get the pistons out soon and see what the rings look like. If that much oil is getting in the cylinders but not thru the rings or guides how could it get there?

|

||

Posted on: 2011/9/15 3:17

|

|||

Transfer Transfer

|

|||

| tjpreul | Re: 93 LT1 rebuild question | ||

|

Elite Guru

|

Was the pcv hose that connects to the tb full of oil?

|

||

Posted on: 2011/9/15 3:27

|

|||

|

_________________

Vegas wasn't built on winners. '92 auto, MSD, Banski, Taylor wires, SS lines, C5 rims, 3.07 gears, white gauges, seats from a '96. Motor: Forged rotating assy, Probe pistons, CC valvetrain, AFR heads, Procharger P1SC |

|||

Transfer Transfer

|

|||

| bam | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

Quote:

No it wasn't, it did have a coating of oil though. The PCV on the LT1 actually attaches to a bung on the intake, the hose looks like a U shape, one part of the U attaches to the PCV valve the other to the intake bung. I don't know where it vents, but it is inside the intake somewhere. Maybe some will chime in who knows more about the PVC and how it works on the LT1 and how it might pull oil into the intake. Would oil coming in the PCV puddle on the closed intake valve? There was oil in the TB though, and in the tube that comes from the valve cover to the TB, for oil to get all the way back to the TB when there should be only vacuum there must mean that pressure in the crank case must of overcome the vacuum from the PCV valve right? |

||

Posted on: 2011/9/15 3:57

|

|||

Transfer Transfer

|

|||

| tjpreul | Re: 93 LT1 rebuild question | ||

|

Elite Guru

|

Quote:

The one on the passenger side is the one I meant. It is a breather, but it also uses a PCV valve that sits in the valve cover. The tb pulls a constant vacuum from the valve cover, so if it wasn't closing this would be your oil issue. |

||

Posted on: 2011/9/15 16:08

|

|||

Transfer Transfer

|

|||

| rklessdriver | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

If it's the PVC the entire intake tract will be coated in oil. Inside of the manifold, cyl head intake runners ect will all have a film of oil on every inch of them.

PVC valves do get stuck open or the little fiber disk gets broken and at that point it's just a tube attached to an oil source on one end and a vaccum source on the other..... you can figure out what happends from there... but the LTX system is very well baffeled thru the intake manifold into the lifter valley.... not much oil flying around in there like the small confines of a rocker cover..... I don't think that could be the entire source your problem. With 26% showing on the leak down I'm betting you'll find a stuck ring or busted ring land on one of the pistons.... Also take a close look at that vertical scoring on the cyl wall.... classic sign of an over heated piston from detonation. .0015 out of round is about right for a high mile LTX used bore but the .002 taper is pushing the edge of crap and IMO the block will have to bored to clean up. Will |

||

Posted on: 2011/9/15 21:47

|

|||

|

_________________

1984 Corvette. 434 SBC with a Powerglide. Best pass - 8.48@160MPH 1.23 60ft on MT 275/60R15 Radials. 1972 Corvette. LS5 454 BBC with M20 4 speed. Best Pass - Doing good to just pass a gas station. |

|||

Transfer Transfer

|

|||

| bam | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

Took #4 piston out, no broken rings but lots of crud around the sides of the piston and around the rings. The rod bearings are toast, full of scoring and a spot in the middle where it looks like the surface is completely worn away. Putting the valves back in the guides I can wiggle them a bunch, it seems to me that there should be almost no play if the valves and guides were in spec?

The intake is completely black inside but not oily. It's more like carbon deposits, gritty and dry (from the EGR?) Cylinder #4 has a big galled spot, it looks very strange and very smooth. I'll try to get some more pix soon. Still have not figured out the download for pix yet. |

||

Posted on: 2011/9/16 1:17

|

|||

Transfer Transfer

|

|||

| bam | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

Mic'd the valve guides and the valves, there is typically a .004-.005 difference between the two, the guides being worn that much bigger than the valve stem. That to me is pretty bad, I can't see why the machine shop guy here said the valve guides were fine? The piston skirts are typically .003-.004 smaller than the cyl bore which was .003 over, don't know what that translates into as far as way too much clearance or not.

|

||

Posted on: 2011/9/17 14:21

|

|||

Transfer Transfer

|

|||

| rklessdriver | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

Piston to wall clearance varies by mfgr as does where your suposed to measure on the skirt....

However factory cast/hyper piston is around .001-.0015 piston to wall - measured half way down the skirt. .003 on a 4" bore cast/hyper piston is on the loose side. Of course IMO the only repair option here is bore and hone .030 and buy new pistons. Valve Guide clearance should be .002 INT and .0025 EX (at most) in a hi performance engine with cast iron guides which is what the LTX has stock. Factory is probally a lil tighter than that. I reckon the machinest you took stuff to is a moron - because .004-.005 on the guides is slap worn out. You got a couple repair options, cheapest is to knurl the factory guides.... the next cheapest is you can put in bronze K-Liners.... the best option is just replace the entire guide insert but it's the most labor intensive and expensive. Will |

||

Posted on: 2011/9/17 22:51

|

|||

|

_________________

1984 Corvette. 434 SBC with a Powerglide. Best pass - 8.48@160MPH 1.23 60ft on MT 275/60R15 Radials. 1972 Corvette. LS5 454 BBC with M20 4 speed. Best Pass - Doing good to just pass a gas station. |

|||

Transfer Transfer

|

|||

| mistaben | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

it was my understanding that after .003 you need to start looking at freshening up the block. doesn't matter if it is a rod or cynlinder wall....

if it's on a crank/rod after .0035 or .004 you will start getting knocking pretty quickly. at least that was my understanding and im on my 3rd or 4th engine now.... |

||

Posted on: 2011/9/19 4:24

|

|||

Transfer Transfer

|

|||

| mistaben | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

Quote:

I agree with all of the above here. just my 2 cents. stay away from modifying the engine while your inside and your rebuild can stay cheap.... if you start modifying it, it can get expensive quickly... and you will need to retune it when your finished too. |

||

Posted on: 2011/9/19 4:26

|

|||

Transfer Transfer

|

|||

| bam | Re: 93 LT1 rebuild question | ||

|

Senior Guru

|

thanks guys! I am staying with the stock stroke, bored 30 over, stock rods, or maybe the Scat Qlite rods but 5.7 len for sure. I want to go with trick flow heads and think they will match my hot cam pretty well. These pistons; http://cgi.ebay.com/ebaymotors/Chevy- ... ories&hash=item4cfa02a6bf

|

||

Posted on: 2011/9/22 1:25

|

|||

Transfer Transfer

|

|||

You can view topic.

You cannot start a new topic.

You cannot reply to posts.

You cannot edit your posts.

You cannot delete your posts.

You cannot add new polls.

You cannot vote in polls.

You cannot attach files to posts.

You cannot post without approval.

|

|